Types of Auto Parts Suppliers: How the Production Chain Works

Content

- 1 Tier 0: Automaker — The Final Assembly Point

- 2 Tier 0.5: Engineering as a Division

- 3 Tier 1: System Suppliers

- 4 Tier 2: Component Suppliers for Tier 1

- 5 Tier 3: The Raw Material Providers

- 6 Summary: How It Works in Practice

- 7 Genuine, OE, OEM, Aftermarket — What’s the Difference and What to Choose?

- 8 How Car Manufacturing Works — and What It Means for Parts

- 9 Why Automakers Don’t Produce Everything Themselves

- 10 Genuine, OEM, OE, Aftermarket: What They Mean and How They Differ

- 11 How to Choose Wisely

- 12 A Closer Look at Each Type

- 13 How to Decide?

- 14 Conclusion

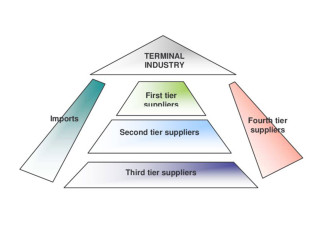

The world of auto parts isn't a chaotic warehouse of metal—it’s a meticulously built hierarchy. To understand where your car parts come from, and why the same component can have five different labels and price tags, you need to grasp the supplier structure. From raw materials to advanced control units—everything is part of a complex ecosystem.

Tier 0: Automaker — The Final Assembly Point

Tier 0 refers to the automaker itself. This is where all components come together into a single machine that becomes a car. Automakers don’t make every bolt themselves—they set specifications, select suppliers, and control quality. The factory is the place where systems from different supply levels unite into a finished product.

Tier 0.5: Engineering as a Division

This is a rare but important level. These companies are legally separate but functionally embedded within the automaker’s ecosystem. They develop electronics, design specialized components, and test integrated systems. In EVs and autonomous technologies, Tier 0.5 can play a pivotal role. Legally independent, they operate like an internal division of the OEM.

Tier 1: System Suppliers

Tier 1 suppliers are the closest partners to the automaker. They deliver complete systems: transmissions, suspensions, brake assemblies, engines. Think of giants like ZF, Bosch, AISIN, or Brembo. They don’t just supply parts—they handle quality control, compatibility tests, and sometimes even installation on the production line. Some carmakers are also Tier 1 suppliers for others.

Tier 2: Component Suppliers for Tier 1

This level is mostly invisible to the consumer, yet it's where much of the magic happens. Tier 2 suppliers deliver subcomponents to Tier 1—buttons, motors, fans, sensors. For example, if Bosch makes an HVAC system, the fan motor inside might come from a Tier 2 supplier. This is the tier professionals often deal with in daily operations.

Tier 3: The Raw Material Providers

Tier 3 is the base of the pyramid. Raw metals, plastics, fasteners, rubber seals, technical fluids—they supply the entire chain, including Tier 2 and Tier 1. While their role might seem basic, the quality of materials directly affects the longevity of the entire system.

Summary: How It Works in Practice

When you hold a part labeled Maserati in your hand, chances are it was manufactured by a Tier 1 or Tier 2 supplier. The carmaker simply rebranded it. That’s why it’s fair to ask: why am I paying double for the same brake pad?

The answer lies in the labeling. This is where the distinction between Genuine, OE, OEM, and Aftermarket begins.

Genuine, OE, OEM, Aftermarket — What’s the Difference and What to Choose?

If you’ve ever needed to replace a car part, you’ve likely come across these acronyms. Genuine, OEM, OE, Aftermarket—they sound similar but have significant differences.

This isn’t a dry technical manual—it’s a clear, practical guide to help you understand the terms and make smart decisions quickly.

How Car Manufacturing Works — and What It Means for Parts

A modern car is not the product of a single factory. It's the result of coordination between dozens—or even hundreds—of subcontractors who make individual components. The automaker acts more like the chief architect, assembling everything into a single system.

The process starts with digital design, followed by body stamping, welding, painting, assembly of drivetrains, electronics, interior—then multiple layers of quality control before the car reaches the dealer.

Why does this matter? Because not all parts are made by the brand whose logo is on the hood. And that’s where the difference between OEM and OE comes in.

Why Automakers Don’t Produce Everything Themselves

- Specialization: Each group of components is its own engineering domain. Companies like Bosch, ZF, or Valeo have decades of expertise in specific niches like brakes, electronics, or lighting. Automakers benefit from their deep specialization.

- Cost savings: External suppliers can produce the same components for less—thanks to economies of scale, streamlined processes, and less bureaucracy.

- Access to innovation: Suppliers working with multiple brands adopt new technologies faster. Automakers get higher-quality solutions more quickly than if they developed them in-house.

Genuine, OEM, OE, Aftermarket: What They Mean and How They Differ

Genuine

These are official parts sold under the carmaker’s brand. They are identical to those installed at the factory. Packaging, part numbers, labeling—all match the automaker’s documentation.

Best for: when 100% authenticity, warranty, and guaranteed fit are crucial.

Downside: highest price point.

OEM (Original Equipment Manufacturer)

These come from the same manufacturers that supply the automaker’s assembly line—but without the car brand’s logo. In other words, the same part in different packaging.

Best for: saving money without compromising quality.

Benefit: usually 20–40% cheaper than Genuine.

OE (Original Equipment)

Parts that meet factory specs but are not made by the same supplier as on the production line. They're compatible but may have slight engineering or material differences.

Best for: minor replacements when OEM isn’t available.

Drawback: quality varies by brand—you need to know who you're buying from.

Aftermarket

These are all parts made by third parties. Some are high-quality alternatives (like Mahle or Lemförder), others may be of unknown or questionable origin.

Best for: cost-saving or performance tuning.

Risk: potential differences in dimensions, materials, or durability.

How to Choose Wisely

- Assess your vehicle’s value. For classic or high-end cars, Genuine or OEM is a better fit.

- Consider the part's importance. Braking systems aren't the place to cut costs.

- Verify the supplier. A cheap substitute might be a counterfeit.

A Closer Look at Each Type

Genuine — Original Parts from the Automaker

These parts are sold under the carmaker’s brand—even if a Tier 1 or Tier 2 supplier actually made them. Delivered through official channels, they offer perfect fit and performance, but at a premium price.

Often, you’ll find that under the holographic sticker lies the logo of a familiar supplier. In such cases, you’re paying more for the box than the part itself.

OE (Original Equipment) — Same Quality, No Badge

OE parts are identical to those used on the production line, just without the automaker’s branding. Sold directly by distributors, they offer the same specifications and materials. The only difference is the packaging.

This is the smartest option if you want “factory quality” without overpaying for the brand name.

OEM (Original Equipment Manufacturer) — A Bit More Complex

OEM parts are made by a supplier that provides at least one component to the automaker. However, the specific part you’re buying may not have been installed at the factory. It's built to spec, and may be OE or a high-quality alternative.

OEM is often confused with OE. The key difference: OEM is a brand licensed to make the part but doesn’t guarantee it’s factory-installed.

Aftermarket — Variety and Full Freedom

These are parts outside the official supply chain. Some are counterfeit, others are cutting-edge. Companies like Akrapovič or AFE don’t have OEM contracts but their products are used in tuning, motorsports, and regular repairs.

Aftermarket means freedom of choice—but also responsibility. Know your supplier, check reviews, look for test results and brand reputation.

How to Decide?

- Start with OE for best value and factory-spec quality.

- If you’re willing to pay for the label, go Genuine.

- OEM is a smart middle ground—great quality without obsession over branding.

- Aftermarket suits experienced buyers or performance enthusiasts.

Conclusion

Auto parts aren’t just metal and rubber—they’re the product of a complex system involving thousands of engineers, managers, and suppliers. Understanding the supply chain helps you save money and choose truly reliable solutions.

At MIE Corporation, we work with suppliers across all tiers and help you find parts that match not just your budget but your expectations for quality. We know who stands behind what—and we’re here to give you honest guidance without unnecessary costs or compromises.